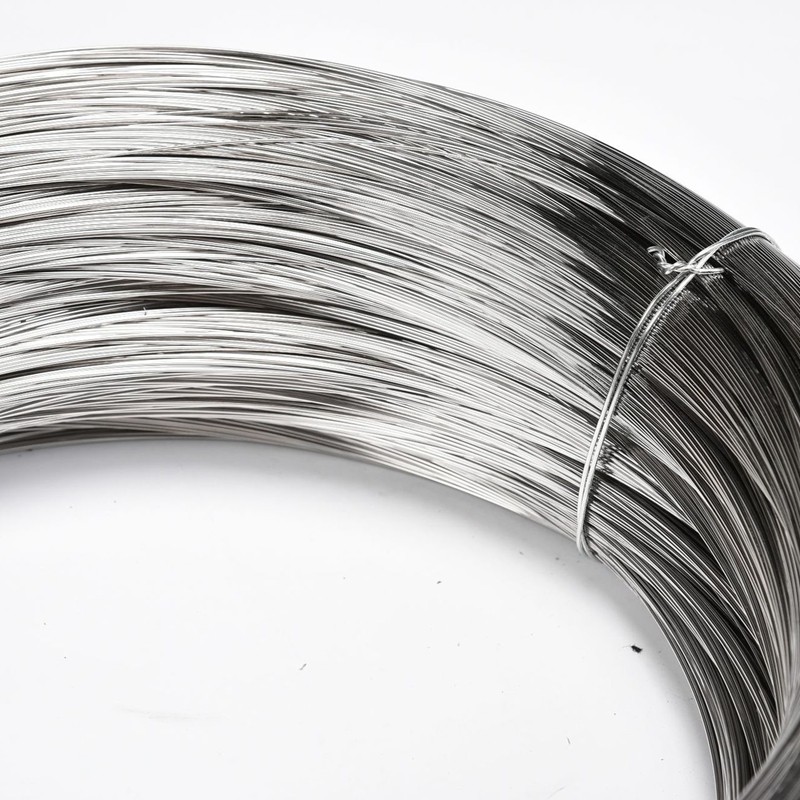

Stainless steel wire 316 SS 1mm

Product Description

Stainless Steel Wire 316:

316 stainless steel wire is a type of stainless steel wire with low molybdenum content compared to type 304. Due to its molybdenum content,

316 stainless steel wire has superior properties than regular stainless steel wire. At high temperatures and when the sulfuric acid concentration is below a certain percentage,

316 stainless steel wire is widely used. It also has good resistance to chloride attack and is therefore suitable for use in marine environments. Due to its superior properties, 316 stainless steel wire is becoming popular in the industrial market. It also has good welding performance and can generally be welded using all standard welding methods. In most cases, to improve product quality and obtain better corrosion resistance, 316 stainless steel wire requires annealing after welding, which greatly improves the corrosion resistance of stainless steel products and allows them to be put into normal production.

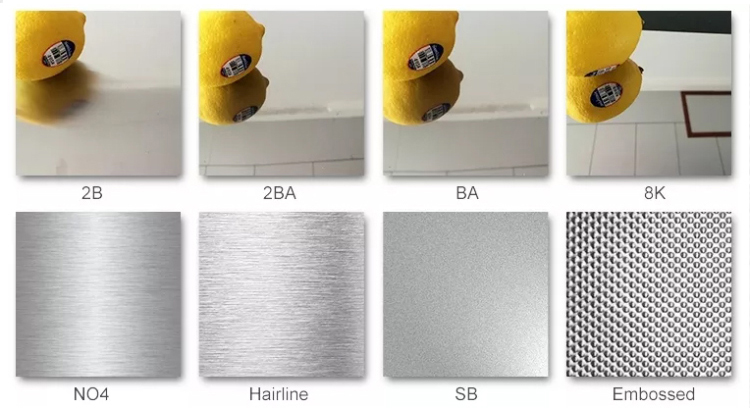

Surface Treatment

Product Parameters

| Grade | 201,202,301,302,303,304,304L,304N1,309S,310S,

316,316L,316Ti,321,904,904L,2205,2507,etc. |

| Surface | BA/2B/No.1/No.4/8K/HL |

| Standard | ASTM, GB, JIS, DIN, EN, AISI |

| Variety | Soft wire,hard wire,spring wire,electrode wire,etc. |

| Size | 0.15~20mm or as required |

| MOQ | 1 Ton |

| Payment Term | TT 30% advance in advance and the balance before shipment |

| Delivery Term | EXW, FOB, CIF, CFR, FCA |

| Sample | Available |

| Delivery Time | 7~30 days according to the quantity |

Advantage

316 stainless steel wire has a high resistance to corrosion, making it suitable for use in aggressive environments, such as those with high levels of chloride ions.

316 stainless steel wire has good mechanical and physical properties at high temperatures, allowing it to be used in high-temperature applications.

316 stainless steel wire can be welded using various welding methods, making it easy to fabricate into various shapes and sizes.

Application

1、 Construction engineering field

In the field of construction engineering, stainless steel wire is often used to make steel wire ropes and grids. They can be used for protective nets in high-rise buildings, bridges, and other engineering projects, as well as for the manufacturing of ropes and rigging. Stainless steel wire mesh is also used for indoor decoration, fences, and other aspects, with a dual effect of aesthetics and practicality.

2、 Manufacturing sector

In the manufacturing industry, stainless steel wire also has a wide range of applications. It can be used to manufacture mechanical parts, springs, rivets, and other products, as well as to make safety products such as anti-theft doors, anti-theft windows, and protective masks. In addition, stainless steel wire can also be used in daily necessities such as hooks, hangers, and kitchen utensils.

3、 Petrochemical industry

Stainless steel wire is also widely used in the petrochemical industry. It can be used to manufacture containers such as transportation pipelines, reactors, heat exchangers, as well as corrosion-resistant pumps and valves. Due to its excellent corrosion resistance and high-temperature stability, stainless steel wire is particularly suitable for the production, transportation, and storage of chemicals containing corrosive media such as acids and alkalis.

Aviation

Appliance Production

Ceiling

Kitchen Ware

Tableware

Door

Car Industry

Medical Devices

Packing Transportation

Packaging:Standard seaworthy packaging.

Transport:Generally, we ship from Shanghai, Tianjin, Qingdao and Ningbo ports. We have long-term cooperation with many experienced shipping companies and will find the most suitable one for you.

FAQs

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your enquery.

Yes, we require all international orders to have an ongoing minimum order quantity.

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Generally it is around 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

30% TT in advance and the balance before shipment.