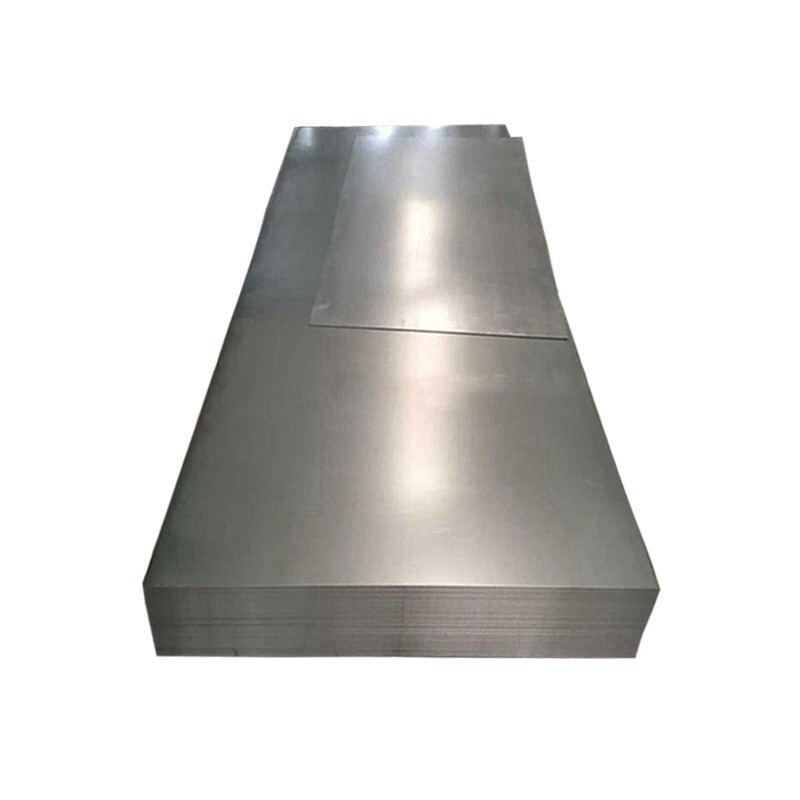

Stainless steel plate 304 SS 10mm

Product Description

Stainless steel plate 304:

304 stainless steel plate is a commonly used stainless steel material, composed of high-strength stainless steel and corrosion resistant alloy, with excellent corrosion resistance and good low temperature strength and mechanical properties, stamping bending and other hot processing good, no heat treatment hardening phenomenon (non-magnetic), the use of temperature range of -196℃~800℃.

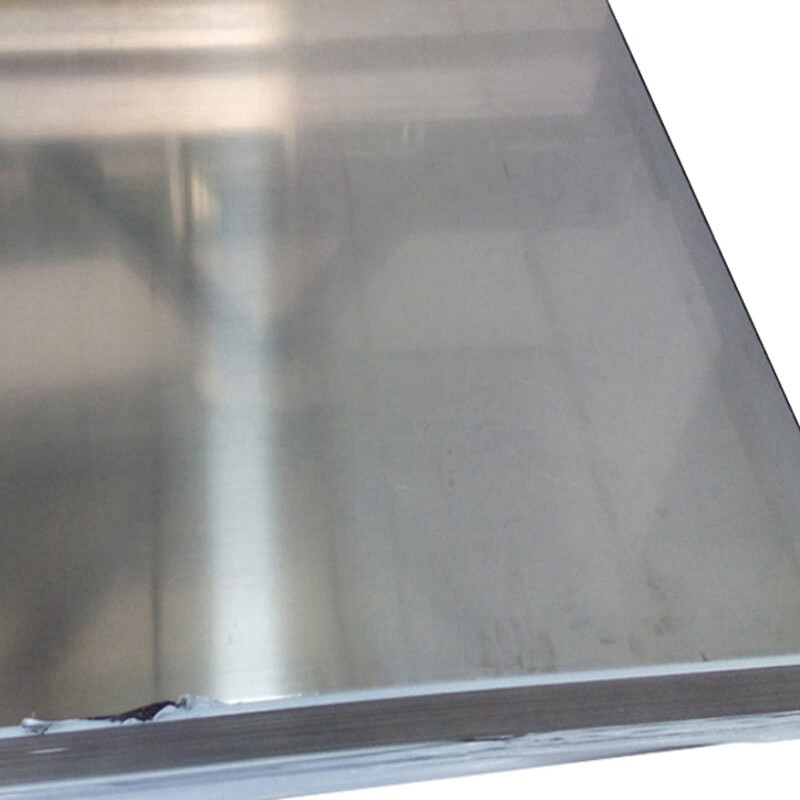

304 stainless steel plate is widely used, with good corrosion resistance, heat resistance, low temperature strength and mechanical characteristics; Stamping bending and other hot processing is good, no heat treatment hardening phenomenon (non-magnetic), so it can resist fire; Normal temperature processing, that is, easy plastic processing because it does not need surface treatment, so simple, simple maintenance and clean, high finish; Good welding performance; The surface is smooth, with high plasticity, toughness and mechanical strength, resistant to acid, alkaline gas, solution and other media corrosion. It is an alloy steel that does not rust easily.

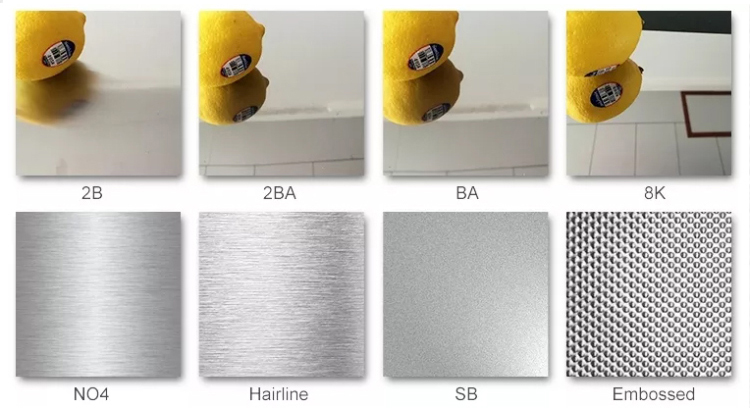

Surface Treatment

Product Parameters

| Grade | 201,202,301,302,303,304,304L,304N1,309S,

310S,316,316L,316Ti,321,904,904L,2205,2507,etc. |

| Surface | BA/2B/No.1/No.4/8K/HL |

| Thickness | 0.3~100mm or as required |

| Width | 300~1500mm or as required |

| Length | 600~6000mm or as required |

| MOQ | 1 Ton |

| Payment Term | TT 30% advance in advance and the balance before shipment |

| Delivery Term | EXW, FOB, CIF, CFR, FCA |

| Sample | Available |

| Delivery Time | 7~30 days |

Advantage

Many sizes to suit your needs, you can buy with confidence.

Many years of production and processing experience, perfect equipment, thoughtful service.

Made of high quality material, not easy to damage, pressure resistant, durable.

Application

1. Architectural decoration: They can be used for exterior walls, interior decoration, ceilings, staircase handrails, and other parts of buildings, giving them a sense of modernity and temperament.

2. Kitchen equipment: Due to the excellent corrosion resistance and hygiene of stainless steel, stainless steel plates are often used to make kitchen equipment, such as kitchen countertops, sinks, stove backplates, etc. They are easy to clean and can resist the erosion of corrosive substances such as food acids and alkalis.

3. Medical equipment: Stainless steel plates are often used to make hand tables, instruments, etc. The antibacterial and easy to clean characteristics of stainless steel make it an ideal choice for equipment.

4. Automotive industry: They can be used to make body shells, exhaust pipes, intake pipes, and other components because stainless steel has good strength, corrosion resistance, and high temperature resistance.

5. Food processing: Stainless steel plates play an important role in the food processing industry. They are often used to make food processing equipment, storage tanks, conveying systems, etc. The hygiene and corrosion resistance of stainless steel make it a material in the food processing industry.

In addition to the above application scenarios, stainless steel sheets are also widely used in fields such as chemical engineering, electricity, shipbuilding, and energy. Due to the advantages of corrosion resistance, high temperature resistance, and stable mechanical properties, stainless steel plates can meet the needs of various special environments.

Aviation

Appliance Production

Ceiling

Kitchen Ware

Tableware

Door

Car Industry

Medical Devices

Packing Transportation

Packaging:Standard seaworthy packaging.

Transport:Generally, we ship from Shanghai, Tianjin, Qingdao and Ningbo ports. We have long-term cooperation with many experienced shipping companies and will find the most suitable one for you.

FAQs

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your enquery.

Yes, we require all international orders to have an ongoing minimum order quantity.

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Generally it is around 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

30% TT in advance and the balance before shipment.