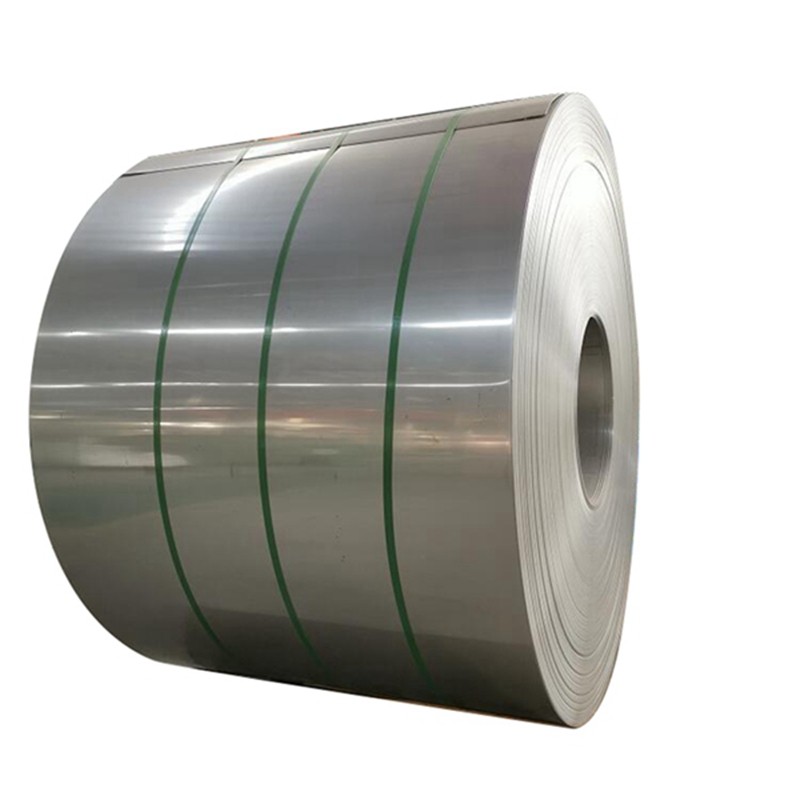

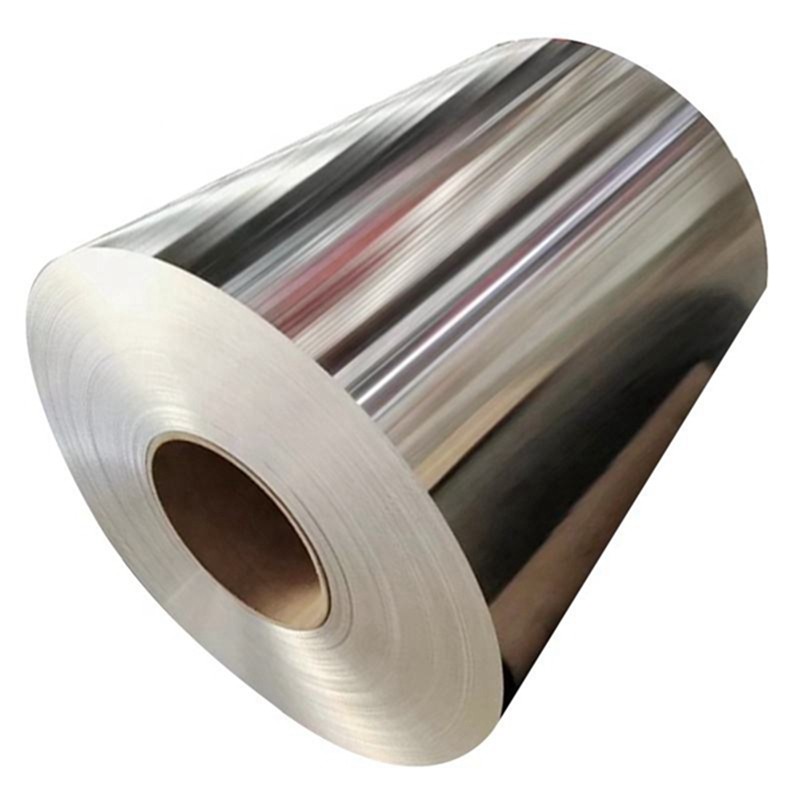

Stainless steel Coil 316 1mm SS

Product Description

Stainless steel Coil 316:

316 stainless steel rings show good corrosion resistance in various atmospheric and corrosive media, while having good strength and plasticity, and can be used in a variety of high strength and complex environments. In addition, 316 stainless steel rings also have good processing properties, and can be made into various shapes and sizes through a variety of conventional and special processing methods to meet the needs of different application scenarios.

316 stainless steel ring has excellent strength and toughness at both high and low temperatures, suitable for a variety of harsh environments, such as Marine applications. In addition, it also has a wide range of applications, such as chemical, pharmaceutical, food processing and other industries

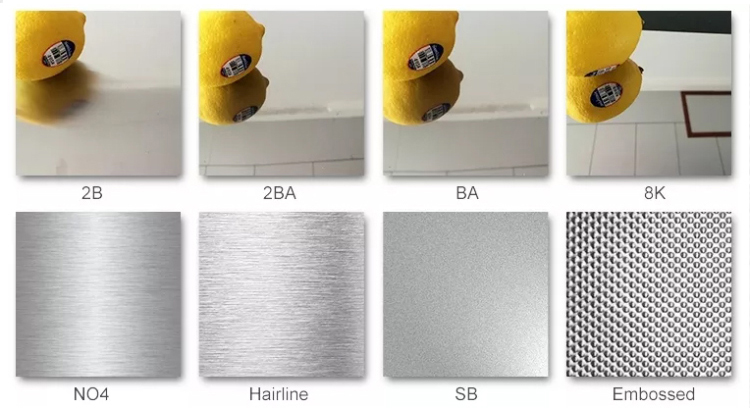

Surface Treatment

Product Parameters

| Grade | 201,202,301,302,303,304,304L,304N1,309S,310S,316,

316L,316Ti,321,904,904L,2205,2507,etc. |

| Surface | BA/2B/No.1/No.4/8K/HL |

| Standard | ASTM, GB, JIS, DIN, EN, AISI |

| Width | 3mm~2000mm or as required |

| Thickness | 0.1mm~300mm or as required |

| Technique | Hot rolled/cold rolled |

| MOQ | 1 Ton |

| Payment Term | TT 30% advance in advance and the balance before shipment |

| Delivery Term | EXW, FOB, CIF, CFR, FCA |

| Sample | Available |

| Delivery Time | 7~30 days according to the quantity |

Advantage

The addition of Mo element to 316 stainless steel can improve its resistance to acid, alkali and chloride pitting.

316 stainless steel performs well at temperatures up to 800°C.

316 stainless steel is easy to weld with TIG or MIG welding and does not require post-weld annealing.

Application

1. Construction field: Stainless steel coils are widely used in building decoration, indoor and outdoor decoration, roofs, doors and windows, railings, and other aspects. Its corrosion resistance enables stainless steel coils to maintain aesthetics and stability for a long time in high humidity or corrosive environments.

2. Household items: Stainless steel coils are used for making kitchen utensils, toiletries, furniture, etc. Stainless steel coils have the characteristics of hygiene, easy cleaning, and durability, which can meet the requirements of home products for aesthetics, functionality, and durability.

3. Automotive industry: Stainless steel coils are used to make automotive components, exhaust systems, body structures, etc. They can withstand harsh road conditions and extreme temperatures, extending the service life of automobiles.

4. Electronic and electrical equipment: Stainless steel coils are used for manufacturing electronic equipment casings, electronic components, battery materials, etc. Stainless steel coils have advantages such as high-temperature oxidation resistance, corrosion resistance, and good conductivity, which can effectively protect the stability and safety of electronic equipment.

5. Medical devices: Stainless steel coils are widely used in the manufacturing of medical devices, such as surgical instruments, medical instruments, operating tables, etc. Its hygiene, cleanliness, and corrosion resistance make stainless steel coils an important material in the medical industry.

6. Ship navigation: Stainless steel coils are widely used in the fields of shipbuilding, marine engineering, and marine equipment. Stainless steel coils can resist the corrosion of seawater, allowing ships to navigate for long periods of time in harsh marine environments.

7. Other fields: Stainless steel coils are also used in industries such as food processing, petrochemical materials, petrochemical, chemical equipment, energy equipment, etc., meeting the requirements of various industries for material strength, durability, and aesthetics.

Aviation

Appliance Production

Ceiling

Kitchen Ware

Tableware

Door

Car Industry

Medical Devices

Packing Transportation

Packaging:Standard seaworthy packaging.

Transport:Generally, we ship from Shanghai, Tianjin, Qingdao and Ningbo ports. We have long-term cooperation with many experienced shipping companies and will find the most suitable one for you.

FAQs

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your enquery.

Yes, we require all international orders to have an ongoing minimum order quantity.

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Generally it is around 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

30% TT in advance and the balance before shipment.