Round Copper Rod C10700

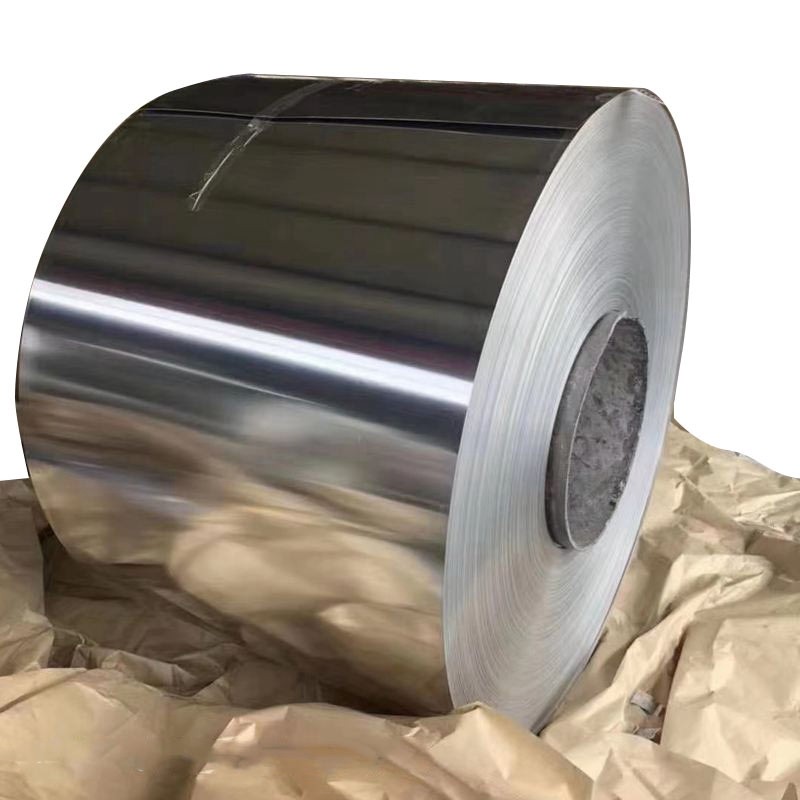

Product Description

Round Copper Rod C10700:Copper has good electrical and thermal conductivity, excellent plasticity, easy hot pressing and cold pressure processing, a large number of used in the manufacture of wire, cable, brush, electric spark special electrical corrosion copper and other products requiring good electrical conductivity.

Commonly used copper alloys are divided into three categories: brass, bronze and white copper. Pure copper is a purple red metal, commonly known as "red copper", "red copper" or "red copper". Copper or copper is named for its purplish red color. It is not necessarily pure copper, and sometimes a small amount of deoxidation elements or other elements are added to improve the material and performance.

Copper is therefore also classified as copper alloys. Chinese copper processing materials can be divided into four categories according to composition: ordinary copper (T1, T2, T3, T4), oxygen-free copper (TU1, TU2 and high-purity, vacuum oxygen-free copper), deoxidized copper (TUP, TUMn), and special copper (arsenic copper, tellurium copper, silver copper) with a small amount of alloying elements. The electrical and thermal conductivity of red copper is second only to silver, and it is widely used in the production of conductive and thermal equipment. Copper has good corrosion resistance in atmosphere, seawater and some non-oxidizing acids (hydrochloric acid, dilute sulfuric acid), alkali, salt solution and a variety of organic acids (acetic acid, citric acid).

Product Parameters

| Grade | Pure Copper:C10100/C10200/C11000/C12000/C12200

Copper Alloy:C14500/C17200/C17300/C17510/ C18150/C19200/C19210/C19400 Brass:C22000/C23000/C24000/26000/26800/27000 Lead Brass:C33000/CuZn36Pb3/C35000/C35300/C36010/C37000/ 37700/C38000/C38500/CuZn39Pb3/CuZn40Pb2 Tin Brass:C44300/C44500/C46400/HSn90-1 Aluminum Brass:C68700/HAl77-2/HAl66-6-3-2/HAl64-3-1 Tin Bronze:C51000/C51100/C51900/C52100/54400/ CuSn4/CuSn5/CuSn5Pb1/CuSn6/CuSn8 Aluminum Bronze:C60800/C61300/C61900/C62300/C63000 Copper Nickel Alloy:C70400/C71500/C70600/C70620/C73500/75200/76200/C77000 |

| Standard | AISI,ASTM, EN, BS, GB, DIN, JIS |

| Temper | Soft, 1/4 Hard, 1/2 Hard, Hard, Extra Hard |

| Diameter | 3~500mm or as required |

| Surface | Mill,Polished,bright or customized |

| Package | Standard seaworthy package |

| Payment Term | Over $10,000, pay 30%T/T deposit in advance, 70%T/T the balance before shipment, under $10,000, pay in full by T/T. |

| Delivery Term | EXW, FOB, CIF, CFR, FCA |

| Sample | Available |

| Delivery Time | 7~30 days according to the quantity |

Advantage

Copper has good electrical conductivity and heat resistance Conductive, corrosion resistant and Good processing performance, can be welded and brazed, and has good low temperature performance.

Copper surface smooth, clean, no burrs. And has good mechanical properties, heat resistance and corrosion resistance. Widely used in all kinds of machined parts.

Good mechanical properties, good plasticity in hot state, good plasticity in cold state, good machinability, convenient for fiber welding and welding.

Application

1、 Electrical field

Copper bars, as a good conductive material, are widely used in the manufacturing and maintenance of electrical equipment. For example, copper bars can be used for electrical grounding and wiring. Especially in the case of high current transmission, copper bars are a reliable conductive material. Therefore, copper bars are widely used in fields such as power systems and railway electrical equipment.

2、 Mechanical field

Copper bars have good machinability and thermal conductivity, making them widely used in the field of mechanical processing. Copper bars can be used for the manufacturing of various mechanical components such as bearings, screws, and nuts. In addition, copper bars are also widely used in some mechanical equipment that require corrosion resistance.

3、 Chemical industry

Copper rods can also be used for manufacturing chemical equipment and chemical reactors. Because copper rods are not easily corroded during chemical reactions and can withstand harsh working conditions such as high temperature and pressure. Therefore, copper rods are often used for manufacturing equipment such as acid and alkali containers and furnaces.

In addition to the above three fields, copper bars can also be used in fields such as smelting, shipbuilding, aviation, and aerospace. In summary, copper bars are a very commonly used metal product with a wide range of applications.

Automotive Industrv

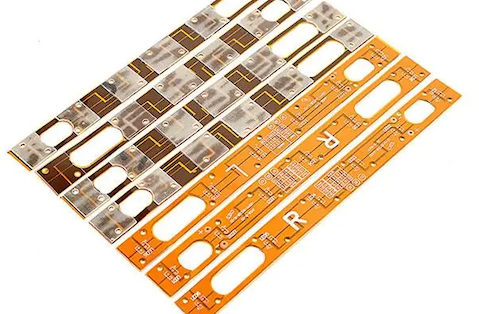

Chip Circuit

Power Transmission

Communication Engineerina

Machiner Manufacturing

Light Industry

Leadframes

Communication Cables

Packing Transportation

Packaging:Standard seaworthy packaging.

Transport:Generally, we ship from Shanghai, Tianjin, Qingdao and Ningbo ports. We have long-term cooperation with many experienced shipping companies and will find the most suitable one for you.

FAQs

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your enquery.

Yes, we require all international orders to have an ongoing minimum order quantity.

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Generally it is around 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

30% TT in advance and the balance before shipment.