What are the specifications of copper strips?

04-28-2024

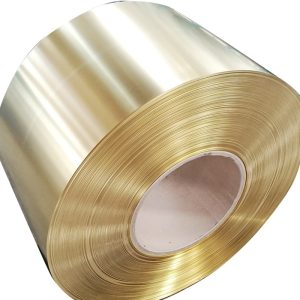

Copper strip is an important material widely used in electrical, electronic, communication, construction and other fields, with good electrical conductivity, corrosion resistance, easy processing and so on. The specification of copper strip refers to its size, thickness, length, surface treatment and other parameters, which have a crucial impact on the performance and processing effect of copper strip. Below we will introduce the specifications of copper belt and its related knowledge in detail.

1) The size of the copper strip

The size specification of copper strip mainly includes two aspects: width and thickness. The width is generally in millimeters (mm), and the common copper strip width is 10mm, 15mm, 20mm, 25mm, 30mm, etc. Thickness is generally millimeter (mm) or micron (μm) as a unit, common copper strip thickness is 0.1mm, 0.2mm, 0.3mm, 0.5mm, 1mm and so on. Different sizes are applicable to different application scenarios and need to be selected according to actual requirements.

2) The length specification of copper belt

The length specifications of the copper belt are generally customized according to customer needs, and the common lengths are 1m, 2m, 3m, 5m, 10m, etc. In practical applications, the length of the copper strip can also be cut or spliced according to needs to meet the needs of different scenarios.

3) Copper strip surface treatment specifications

The surface quality of copper strip is also one of the important factors affecting the specification of copper strip. A copper strip with good surface quality can ensure its electrical conductivity and aesthetics, and can also extend the service life of the copper strip. Common copper strip surface treatment methods are bright annealing, pickling, sandblasting, etc. These treatment methods can be selected according to different needs.

4) The strength and safety of 2mm aluminum tube

In practical applications, the strength of 2mm aluminum tubes is excellent. Its high yield strength and tensile strength make it able to maintain good stability when subjected to external forces, and it is not easy to deformation or fracture. At the same time, in the design and manufacturing process, 2mm aluminum tubes usually take into account their use scenarios and safety requirements, and ensure that they have high safety and reliability in practical applications through reasonable structural design, connection methods and other measures.

5) Packaging and identification of copper belt

The packaging and identification of the copper belt are also the contents that need attention in the specification. Packaging methods include roll, plate, etc., which need to be selected according to transportation and storage conditions. In terms of identification, information such as the material, specifications and production date of the copper strip should be included, so that users can clearly understand the relevant information of the copper strip.

5) The production process and application field of copper strip

Production process: The production process of copper strip mainly includes melting, continuous casting, rolling, annealing and other steps. Copper strips with different specifications and properties can be obtained by adjusting production process parameters.

Application: Copper belt is widely used in electrical, electronic, construction, automotive, aerospace and other fields. In the electrical and electronic field, copper tape is mainly used to make wires, connectors, radiators and other components; In the field of architecture, copper belt can be used for decoration, roof materials and other aspects; In the automotive and aerospace sectors, copper strips are used to make conductive connections, heat exchangers and other key components.

5) Summary

The selection of copper strip specifications has an important influence on its application performance and processing effect. In practical applications, it is necessary to select the appropriate copper strip size, thickness, length, surface treatment and material specifications according to the specific use environment and performance requirements. Through in-depth understanding of the specifications of copper belt and its related knowledge, it helps us to better choose and apply copper belt and make greater contributions to the development of various fields.