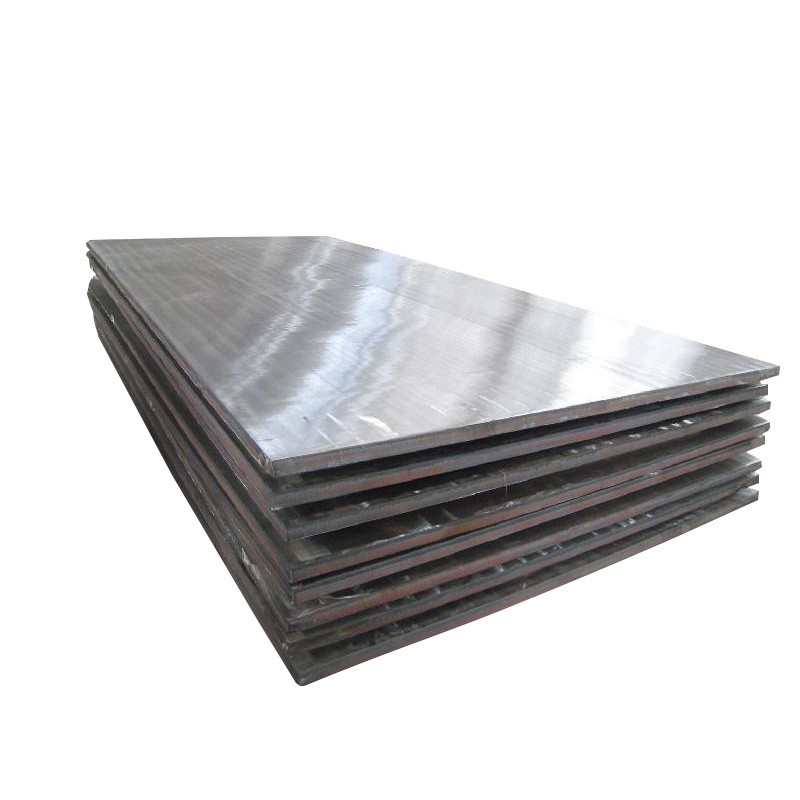

Carbon Steel Sheet

09-28-2023

Carbon steel sheet, a tried-and-true material in various industries, is experiencing a resurgence in popularity as engineers and manufacturers recognize its unique combination of strength and versatility. Carbon steel sheet’s ability to maintain strength and stiffness under a variety of loading conditions has made it a go-to material for a range of applications.

Carbon steel sheet’s mechanical properties are a result of its chemical composition and processing history. Its carbon content allows for the formation of long-chain molecules called “fibers” that provide strength and stiffness to the material. These fibers also provide carbon steel sheet with its ability to withstand fatigue loading—a common cause of material failure—without compromising its mechanical properties.

Carbon Steel Sheet in the Automotive Industry

The unique mechanical properties of carbon steel sheet have opened new frontiers in design freedom for engineers. One such example is in the automotive industry, where designers are using carbon steel sheet to create lighter-weight vehicles that achieve better fuel efficiency. By using thinner gauges of carbon steel sheet—while maintaining its strength and stiffness—engineers can reduce the weight of a vehicle’s body without sacrificing structural integrity.

Carbon steel sheet’s excellent corrosion resistance has also played a role in its popularity resurgence. Its protective oxide layer minimizes rust formation, ensuring the longevity of structures and components made from carbon steel sheet. This corrosion resistance, combined with its strength and stiffness, has made carbon steel sheet a popular choice for outdoor applications such as bridges, buildings, and piping systems.

Carbon steel sheet’s ability to maintain strength and stiffness over a wide range of temperatures has also opened new doors for designers. In cryogenic applications—where materials must withstand extremely low temperatures—carbon steel sheet’s stability has proven advantageous. Its low coefficient of thermal expansion allows for designs that avoid buckling and other mechanical failures commonly associated with other materials at cryogenic temperatures.

Carbon Steel Sheet in Cryogenic Applications

Carbon steel sheet’s popularity is further supported by its ease of processing. It can be cut, bent, and welded using common fabrication techniques—making it a cost-effective and time-efficient material choice for manufacturers. The material’s strength and stiffness can also be further enhanced through various heat treatment processes—offering designers even more design flexibility.

Carbon steel sheet’s unique combination of mechanical, chemical, and processing properties has opened new doors for engineers and manufacturers alike. As designers continue to push the boundaries of design freedom, carbon steel sheet’s popularity is expected to rise even further as they search for lighter, stronger, and more versatile materials to meet their specific needs.