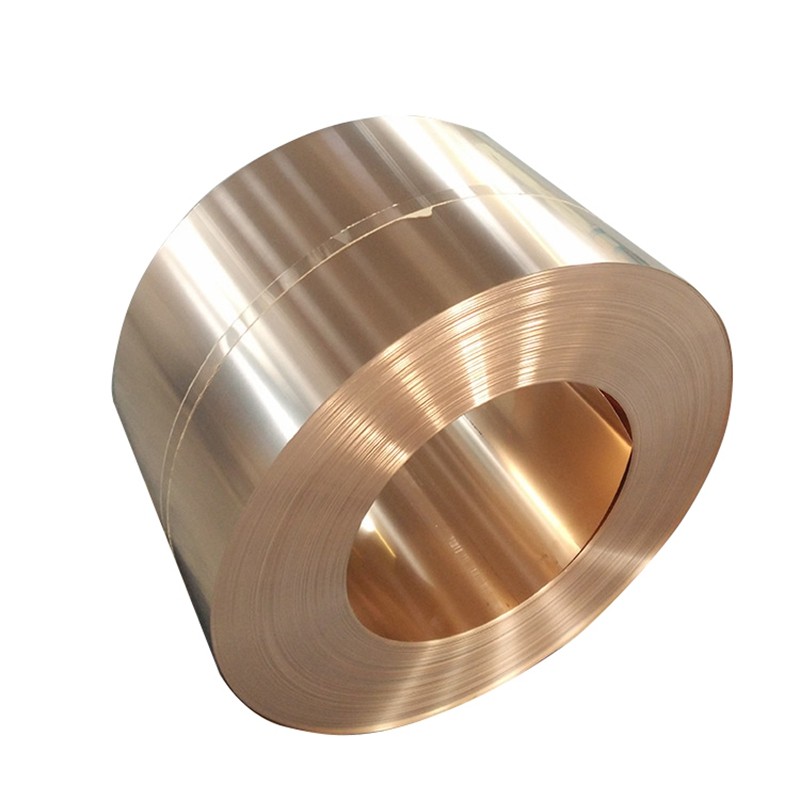

Copper Strip C26000 99.9%

Product Description

Copper Strip C26000:

C26000 copper is a copper-based alloy with zinc as the main alloying element and is named because it is often golden yellow. The simpler brass is a copper-zinc binary alloy, called simple brass or ordinary brass. Brass with different mechanical properties can be obtained by changing the content of zinc in brass. The higher the content of zinc in brass, the higher its strength and slightly lower plasticity. C26000 copper has beautiful color, good process and mechanical properties, high electrical and thermal conductivity, corrosion resistance in the atmosphere, fresh water and seawater, easy cutting and polishing, good weldability and cheap price. Commonly used in the production of conductive and thermal components, corrosion resistant structural components, elastic components, daily hardware and decorative materials.

Product Parameters

| Grade | Pure Copper:C10100/C10200/C11000/C12000/C12200

Copper Alloy:C14500/C17200/C17300/C17510/C18150/C19200/C19210/C19400 Brass:C22000/C23000/C24000/26000/26800/27000 Lead Brass:C33000/CuZn36Pb3/C35000/C35300/C36010/C37000/37700/C38000/C38500/CuZn39Pb3/CuZn40Pb2 Tin Brass:C44300/C44500/C46400/HSn90-1 Aluminum Brass:C68700/HAl77-2/HAl66-6-3-2/HAl64-3-1 Tin Bronze:C51000/C51100/C51900/C52100/54400/CuSn4/CuSn5/CuSn5Pb1/CuSn6/CuSn8 Aluminum Bronze:C60800/C61300/C61900/C62300/C63000 Copper Nickel Alloy:C70400/C71500/C70600/C70620/C73500/75200/76200/C77000 |

| Standard | AISI,ASTM, EN, BS, GB, DIN, JIS |

| Temper | Soft, 1/4 Hard, 1/2 Hard, Hard, Extra Hard |

| Thickness | 0.1~12mm or as required |

| Width | 150~2000mm or as required |

| Surface | Mill,Polished,bright or customized |

| Package | Standard seaworthy package |

| Payment Term | Over $10,000, pay 30%T/T deposit in advance, 70%T/T the balance before shipment, under $10,000, pay in full by T/T. |

| Delivery Term | EXW, FOB, CIF, CFR, FCA |

| Sample | Available |

| Delivery Time | 7~30 days according to the quantity |

Advantage

Copper has good electrical conductivity and heat resistance Conductive, corrosion resistant and Good processing performance, can be welded and brazed, and has good low temperature performance.

Copper surface smooth, clean, no burrs. And has good mechanical properties, heat resistance and corrosion resistance. Widely used in all kinds of machined parts.

Good mechanical properties, good plasticity in hot state, good plasticity in cold state, good machinability, convenient for fiber welding and welding.

Application

1. Brass strip

Brass strip is an alloy containing copper and zinc. Uniform color, excellent processing performance, strong deep drawing ability, easy electroplating and painting, good corrosion resistance and weldability. Brass strips are widely used in electronic components, switch sockets, architectural etching, windshields, fasteners, nameplates, labels, condensers and heat exchangers, hardware products and clothing, dials, lipstick boxes, etc.

2. Tin phosphorus bronze strip:

Tin phosphorus bronze strip is an alloy containing copper, tin, and phosphorus. It has excellent cold workability, electroplating, hot dip plating, and welding performance, high strength, good elasticity, and resistance to seawater and process atmosphere corrosion. Tin phosphorus bronze strips are widely used in high-tech electronic fields such as computer CPU sockets, automotive terminals, mobile phone buttons, and electronic connectors.

3. Copper strip:

Copper strip contains at least 99.90% copper. It has excellent thermal and electrical conductivity, excellent cold and hot processing performance, can be welded and brazed, and has good corrosion resistance. Copper strips are used in the manufacturing of automotive water tank pipes, radiators, electronic components, semiconductors, automobiles, and electrical appliances.

4. Nickel Silver Bar:

Nickel silver strip is an alloy containing copper, zinc, and nickel. It has good cold working performance, good electroplating, hot dip coating, and welding performance, high strength, high elasticity, corrosion resistance, fatigue resistance, shielding, and other properties. Nickel silver strips are widely used in the manufacturing of structural components, elastic components, precision instruments, communication industries, liquid crystal oscillator component shells, and so on.

5. Lead frame strip/KFC:

The Lead Frame Strip/KFC has high conductivity and strength, good cold/hot workability, and welding performance. Mainly used in discrete components, IC lead frame materials, LED lighting, relays, terminal connectors, BGA substrate heat dissipation, dispersed materials, and connectors.

6. Copper nickel silicon strip:

Copper nickel silicon strip is an alloy containing copper, nickel, and silicon. It has good cold working, electroplating, and hot dip tin plating performance, suitable for tin welding and gas shielded welding. It has high yield strength, excellent fatigue resistance, and bending performance, and is mainly used in fields such as large integrated circuits, such as stamping parts, connectors, relay springs, semiconductor components, etc.

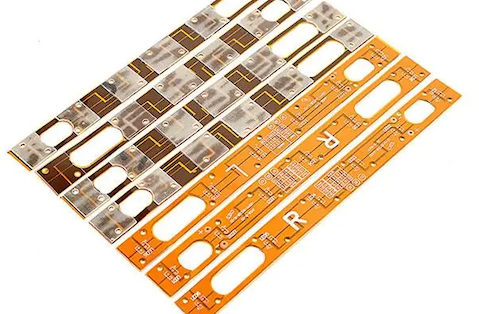

Automotive Industrv

Chip Circuit

Power Transmission

Communication Engineerina

Machiner Manufacturing

Light Industry

Leadframes

Communication Cables

Packing Transportation

Packaging:Standard seaworthy packaging.

Transport:Generally, we ship from Shanghai, Tianjin, Qingdao and Ningbo ports. We have long-term cooperation with many experienced shipping companies and will find the most suitable one for you.

FAQs

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your enquery.

Yes, we require all international orders to have an ongoing minimum order quantity.

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Generally it is around 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

30% TT in advance and the balance before shipment.