Copper Pipe C11000

Product Description

Copper Pipe C11000:

Copper tube C11000 is an electrolytic ductile asphalt (ETP) copper, alloy number 110, with a copper content of up to 99.90% and an oxygen content of about 0.04%. Its conductivity is at least 100% IACS (0.5800 microohms · cm) and sometimes as high as 101.5% IACS. Its electrical and thermal conductivity is the highest of any other copper metal except for oxygen-free grades such as C10200. It is often used for electrical and heat exchanger applications.

Copper pipe C11000 has excellent corrosion resistance and can resist weathering and corrosion of a variety of chemical substances. It is often specially used for occasions with high corrosion resistance requirements. It is suitable for most water quality and can be buried because it resists soil corrosion. It is resistant to non-oxidizing inorganic and organic acids, alkaline solutions and salt solutions.

Product Parameters

| Grade | H95,H90,H85,H80,H70,H68,H65,H63,H62,H59,C1020,C1100,C1221,C22000,

C23000,Tp1,Tp2,H68A,Hpb59-1,Hpb59-1A,Hpb61-1,Tu2, Hsi80-3,Cw614n,Qsn6-6-3,C24000,C26800,C27000, T27300,T27600,T28200,C31400,C33000,C36010,etc |

| Standard | AISI,ASTM, EN, BS, GB, DIN, JIS |

| Temper | Soft, 1/4 Hard, 1/2 Hard, Hard, Extra Hard |

| Outer diameter | 3~328mm or as required |

| Thickness | 0.5~15mm |

| Surface | Mill,Polished,bright or customized |

| Package | Standard seaworthy package |

| Payment Term | Over $10,000, pay 30%T/T deposit in advance, 70%T/T the balance before shipment, under $10,000, pay in full by T/T. |

| Delivery Term | EXW, FOB, CIF, CFR, FCA |

| Sample | Available |

| Delivery Time | 7~30 days according to the quantity |

Advantage

Copper has good electrical conductivity and heat resistance Conductive, corrosion resistant and Good processing performance, can be welded and brazed, and has good low temperature performance.

Copper surface smooth, clean, no burrs. And has good mechanical properties, heat resistance and corrosion resistance. Widely used in all kinds of machined parts.

Good mechanical properties, good plasticity in hot state, good plasticity in cold state, good machinability, convenient for fiber welding and welding.

Application

1. Architecture:In the field of construction, copper pipes are mainly used for manufacturing air conditioning and refrigeration equipment. Due to its good thermal conductivity, it can bring the air to a suitable temperature in a short period of time. In addition, copper pipes are also used in pipeline systems in buildings, such as gas pipelines, water supply pipelines, etc.

2. Electrical:Copper tubes are also widely used in the electronic field, such as in the internal connection lines of electronic products such as mobile phones and computers, which are made of copper tubes. Meanwhile, in the power industry, copper pipes are also used to manufacture electrical equipment, wires, sockets, etc.

3. Chemical Industry:Due to the good corrosion resistance of copper, copper pipes are widely used in the chemical industry. For example, in the oil and gas industry, copper pipes are used for transporting oil and gas, and their high corrosion resistance ensures safety during transportation.

4. Automobile:In the automotive manufacturing process, copper pipes are mainly used for automotive braking systems and electrical connection lines. Based on the good conductivity and corrosion resistance of copper pipes, they can be quickly converted into thermal energy during braking to achieve better braking effects.

Automotive Industrv

Chip Circuit

Power Transmission

Communication Engineerina

Machiner Manufacturing

Light Industry

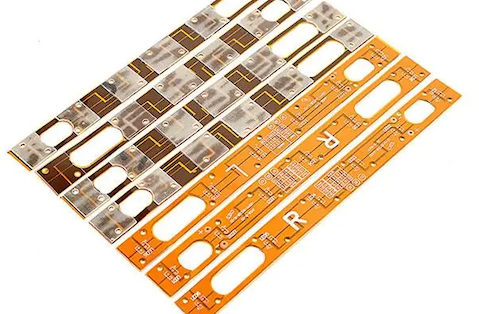

Leadframes

Communication Cables

Packing Transportation

Packaging:Standard seaworthy packaging.

Transport:Generally, we ship from Shanghai, Tianjin, Qingdao and Ningbo ports. We have long-term cooperation with many experienced shipping companies and will find the most suitable one for you.

FAQs

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your enquery.

Yes, we require all international orders to have an ongoing minimum order quantity.

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Generally it is around 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

30% TT in advance and the balance before shipment.