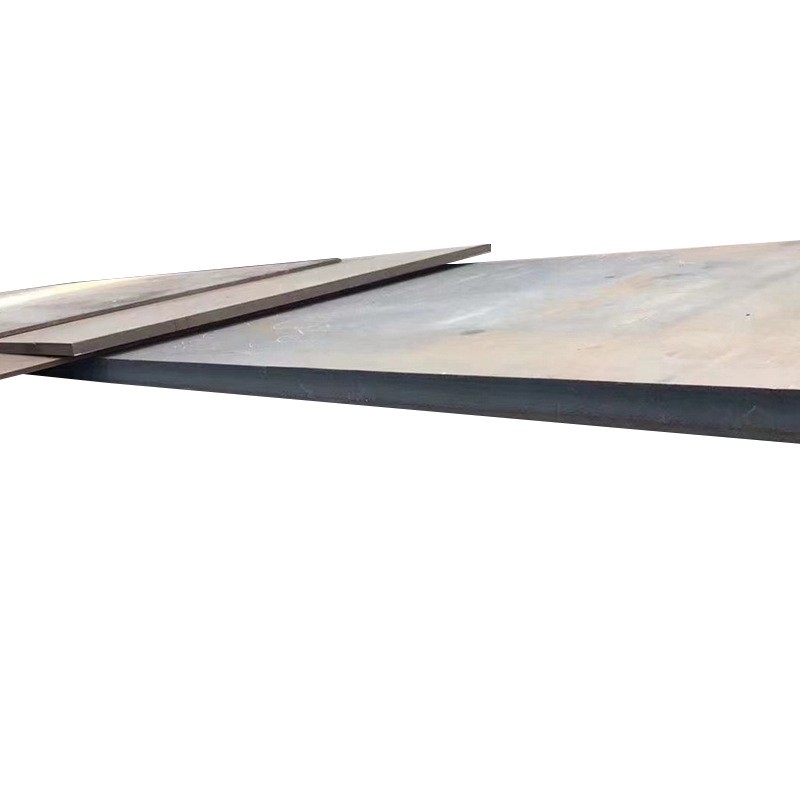

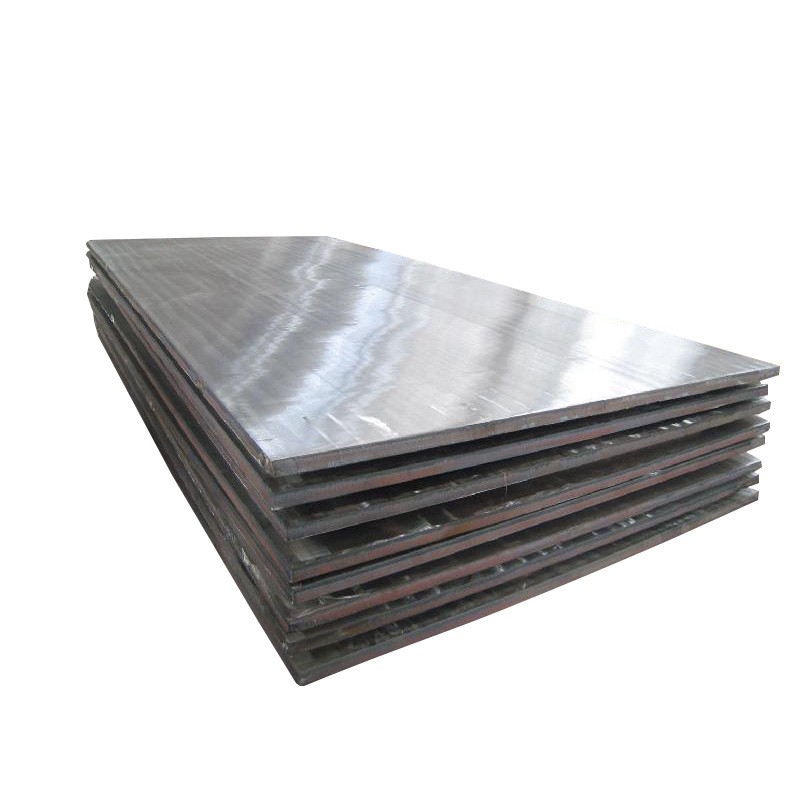

Carbon Steel Sheet St52 Thick 3mm

Product Description

Carbon Steel Sheet St52:Carbon Steel Sheet St52 is a low alloy steel plate. Alloy steel is divided into low alloy steel, medium alloy steel and high alloy steel, as the name suggests, to contain the total amount of alloying elements to be distinguished, the total amount of less than 3.5% is called low alloy steel, 5 ~ 10% is medium alloy steel, more than 10% is high alloy steel. In the domestic custom and special quality of carbon steel and alloy steel is called special steel, the country's 31 special steel enterprises specializing in the production of such steel, such as high-quality carbon structural steel, alloy structural steel, carbon tool steel, alloy tool steel, high-speed tool steel, carbon spring steel, alloy spring steel, bearing steel, stainless steel, heat-resistant steel, electrical steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel, steel. It also includes superalloys, corrosion resistant alloys and precision alloys.

Product Parameters

| Grade | Q195, Q235, Q345; ASTM A53 GrA,GrB; STKM11,ST37,ST52, 16Mn,etc. |

| Standard | ASTM EN DIN GB JIS BA ANSI |

| Technique | Hot rolled/cold drawn |

| Thickness | 1~100mm or as required |

| Width | 500~2000mm or as required |

| MOQ | 1 Ton |

| Package | Standard seaworthy package |

| Payment Term | Over $10,000, pay 30%T/T deposit in advance, 70%T/T the balance before shipment, under $10,000, pay in full by T/T. |

| Delivery Term | EXW, FOB, CIF, CFR, FCA |

| Sample | Available |

| Delivery Time | 7~30 days according to the quantity |

| Remarks | Insurance per to Contract terms;

MTC will be handed on with shipping documents; We accept the third party certification test. |

Advantage

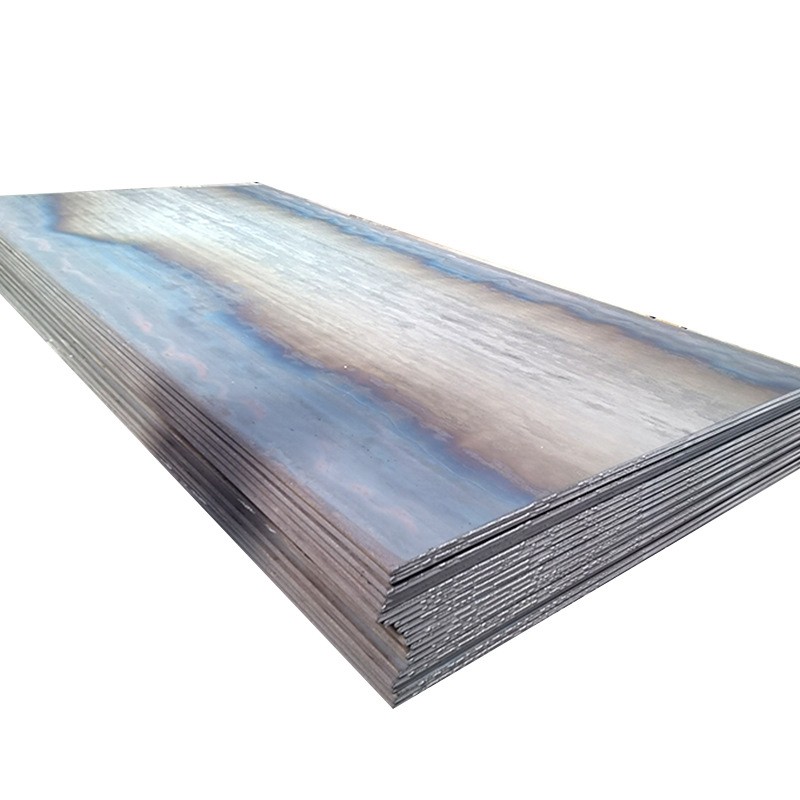

Good processability, good corrosion resistance,good oxidation effect of easycoating, and good weldability.

Wear-resistant steel has high wear resistance and good impact resistance. It can be cut. Bending, welding, etc. It can be connected with other structures by welding, plug welding, etc. Bolt connection, etc.

Carbon steel also typically contains small amounts of silicon, manganese, sulfur, and phosphorus. In general, the higher the carbon content, the greater the hardness of the carbon steel, the higher the strength.

Application

1. Construction engineering: In construction engineering, carbon steel plates are often used to make various components and parts, such as steel beams, columns, steel plates, steel pipes, etc; Used for foundation reinforcement, bridge support, and support structures during tunnel excavation, as well as building steel structure frames.

2. Mechanical manufacturing: In the field of mechanical manufacturing, carbon steel plates are widely used to make various parts and components for automobiles, tractors, railway vehicles, aircraft, etc.

3. Automobile manufacturing: Key components such as brakes, shock absorbers, and frames in automobiles are made of carbon steel plates.

4. Ship manufacturing: In ships and ocean engineering, carbon steel plates can be used to make various structures and facilities, such as decks, bulkheads, pallets, brooms, cabins, etc.

5. Other fields: Carbon steel plates can also be applied in fields such as rail transit, chemical engineering, and petroleum.

Construction

Ship building

Aerospace

Mechanical Manufacturing

Energy industry

Automotive Industry

Power industry

Bridge building

Packing Transportation

Packaging:Standard seaworthy packaging.

Transport:Generally, we ship from Shanghai, Tianjin, Qingdao and Ningbo ports. We have long-term cooperation with many experienced shipping companies and will find the most suitable one for you.

FAQs

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your enquery.

Yes, we require all international orders to have an ongoing minimum order quantity.

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Generally it is around 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

30% TT in advance and the balance before shipment.